Michael Ohmer

Head of Energy and Heat Supply

INP Deutschland GmbH

Werkstraße 5

67354 Römerberg

Germany

Tel. +49 6232 6869-0

michael.ohmer @

@ inp-e.com

inp-e.comvCard

INP International Projects: We offer you more than 35 years of experience in global power plant, large-scale installation construction and the power industry, combined with the reliability of an owner-managed company.

INP offers you an interesting professional future with bright prospects. Now you can become part of our international team.

INP is your reliable partner in the fields of power generation, transmission and distribution, as well as green energy and construction and infrastructure.

![]() We stand for the values of owner-managed SMEs: reliability, responsibility, quality and adherence to deadlines.

We stand for the values of owner-managed SMEs: reliability, responsibility, quality and adherence to deadlines.![]()

![]() Professionalism and reliability are what our customers appreciate. And this has been so for over 30 years.

Professionalism and reliability are what our customers appreciate. And this has been so for over 30 years.![]()

Location: Stuttgart, Germany

Services: Commissioning, Project management, Site management, Documentation, As-built status and data recording, Pre-project planning and tendering, Basic-engineering and pre-engineering, Detail engineering, Installation supervision

Industry Branch/Type of Plant: Green Energy

Client: Stadtwerke Stuttgart GmbH

As part of the „H2 GeNeSiS“ flagship project, the Stuttgart model region aims to build a hydrogen pipeline along the Neckar river as a basis for scaling up the hydrogen economy in the Stuttgart region. Both producers and users will connect themselves to the pipeline, thus developing a far-reaching distribution network.

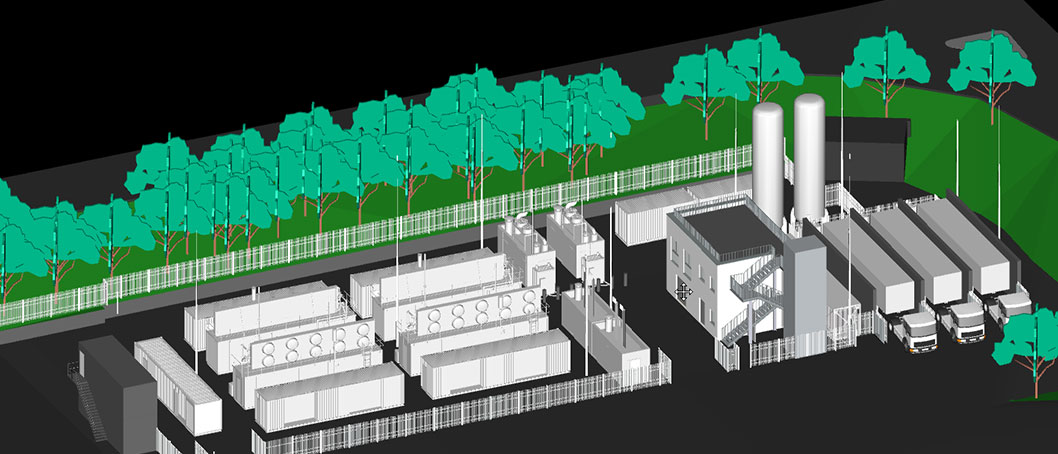

As part of this flagship project, Stadtwerke Stuttgart GmbH is implementing a plant for the production, storage and feed-in of regeneratively produced hydrogen into a pipeline as well as parallel utilization by means of a trailer filling plant. The hydrogen produced is thus used both by local industry and the mobility sector. The plants are to be operated in line with the grid and thus contribute to the flexibility of grid operation.

The aim of the project is to build a process plant for the primary production of hydrogen that is cost-optimized over its entire life cycle. During planning, the focus is not only on construction costs, but also on high availability, high efficiency and low operating costs.

Containerized electrolysis systems with an output of 10 MW and 180 kg H2/h will be used. The hydrogen obtained will have a quality of at least 4.0. The electrolysers supply an H2 pipeline and a loading storage for H2 truck trailers. The heat released from the process will be used to heat a nearby property.

To optimize your visit on our website we use cookies. Some of them are necessary whereas others are helping us to improve and customize the user experience of our website. For this purpose, cookies are used to collect and analyze pseudonymized data of website visitors. You can at any time change or withdraw your consent from the use of cookies.

Further information regarding cookies in this website can be found in our privacy policy